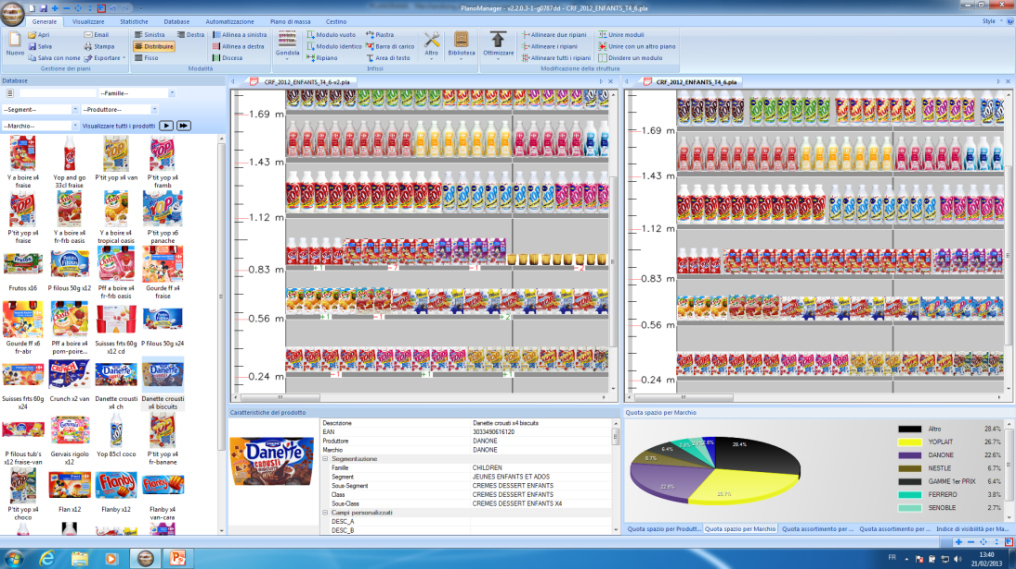

3.1 Assortment Optimization MethodologyĪssortment Optimization Methodology are the methodology formed by retailers to assort the product line, the methodology for the assortment optimization are 80-20 principle, that a retailers target on the top 20% of the product who are performing well and De-listing the under performing products, and also lists some new products according to the products category valuation and forecasting of sales. In this process, according to the market and their target customers, retailers decides on the product categories, brands, and products he want to sell in the stores. Assortment Planning and OptimizationĪssortment planning and optimization is process in which retailers decide the optimal set of product he/she wants to carry within a store or set of stores. This is the very important process of floor plan and plan-o-gram formation, because in each and every store a limited floor space and shelf space is assigned to each product and category. Space is the most important asset of the retailers by the optimization of space the retailers can get the more sales. It is process in which by the help of merchandising guide lines the optimal space is allotted to the Categories, brands, and the product on the basis of different parameters. Space utilization at a typical retail store It is very eye appealing and is easy for the consumers to find brands more quickly.Ī floor plan of Walgreen typical store Sample Plan-o-gram of a Category

Days of Supply – Days of supply could be defined as the number of days ‘stock on shelf’ would last.

0 kommentar(er)

0 kommentar(er)